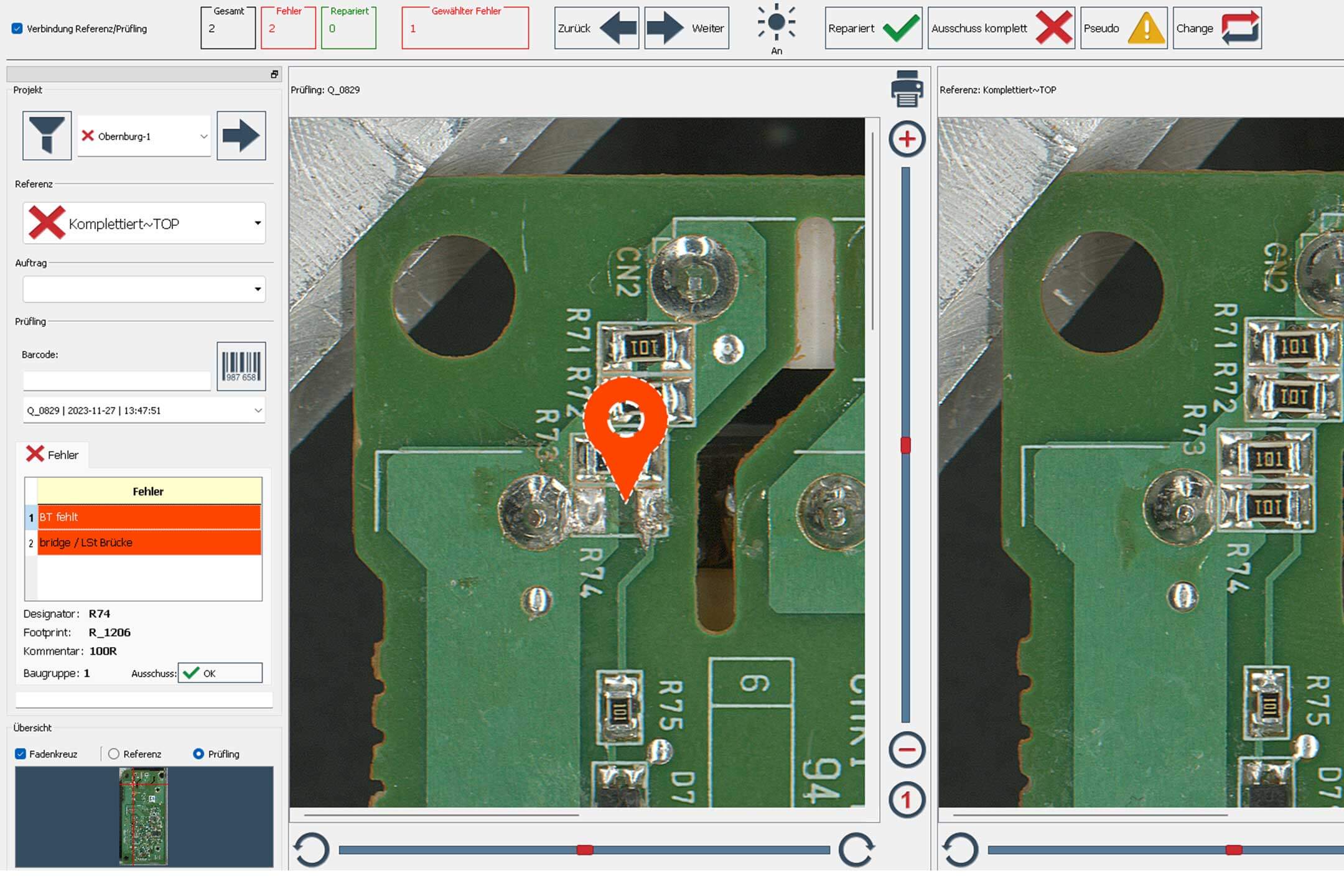

Repair management and documentation

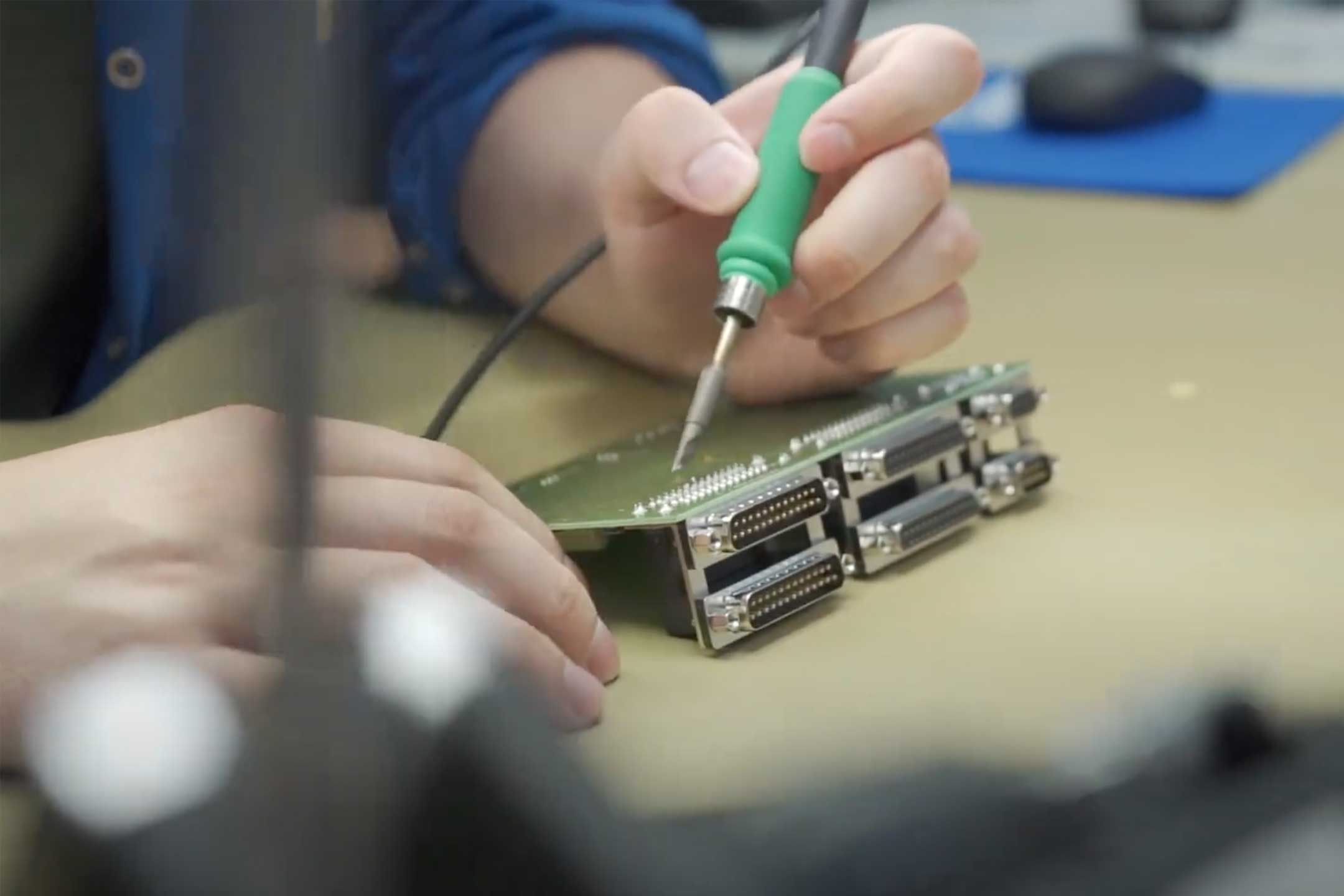

The only thing that remains is soldering.

Reference and defect positions are displayed automatically, as well as the necessary component information. Part repairs, pseudo defect or reject marking, zoom and barcode function are a matter of course.