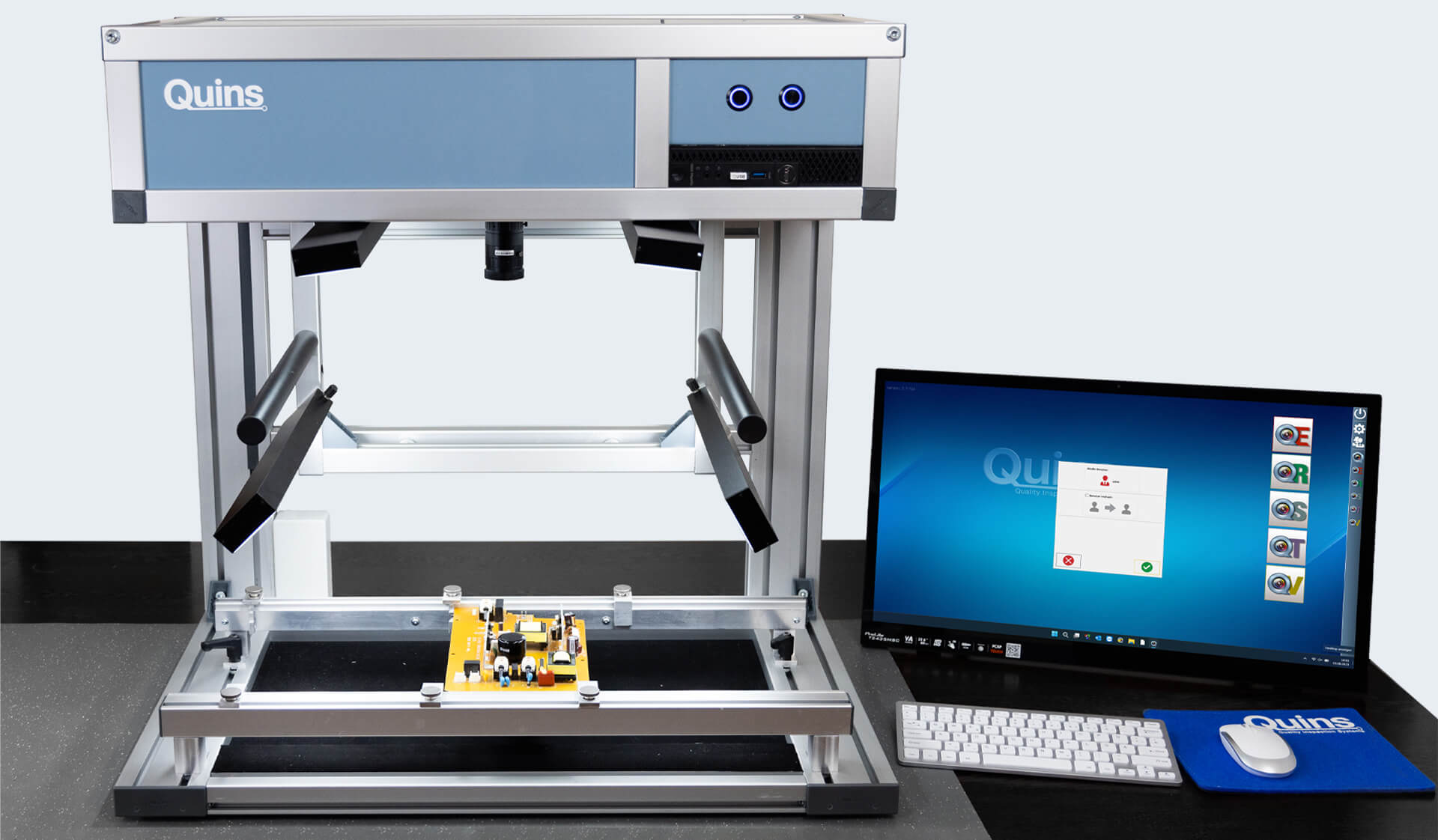

The QUINS advantage

Any simpler would be outrageous.

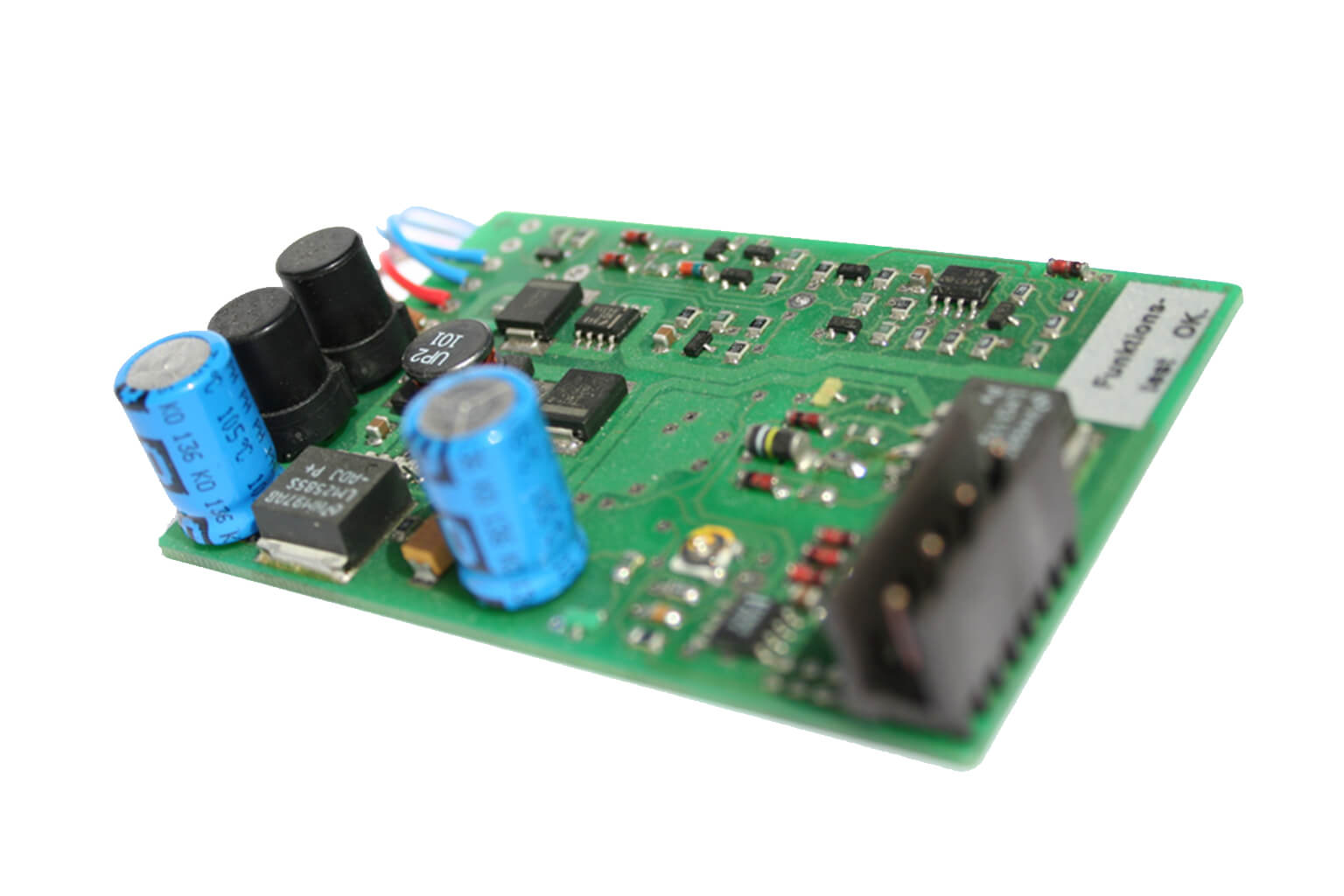

With Quins, complicated visual inspections are a thing of the past. The combination of our hardware and the matching software provides high-resolution images and a simple optical inspection environment. Ready for inspection in no time. Easy.